What should you feed your pet? It’s a very broad question, with many answers. No one individual is the same! That said, at My Pet Nutritionist, we aim to help pet owners make an informed decision. We recommend feeding fresh food to both cats and dogs. In this blog post, we will look at why we recommend fresh feeding, and touch on the different diets available on the market, and look at how each one is manufactured to give you an insight into why we do, or don’t recommend it.

Why Feed Fresh?

Fresh feeding, whether it’s raw, or cooked, uses whole food ingredients to form a complete, and balanced meal. Raw feeding is the closest diet to that of a wild carnivore, and cooked food is the next best option.

Fresh foods are high in moisture which is essential for healthy kidney function, as well as general hydration.

Fresh foods are highly digestible! As the ingredients are all biologically appropriate (which means all suitable for the species being fed), they are easy to digest. Unfortunately the bulk of the ingredients in dry foods are difficult for dogs or cats to digest, which can lead to long term health implications.

The fact that fresh foods are minimally processed is also a huge benefit. The more processed a food is, the riskier it is to general health, both short, and long term. When a food is highly processed, carcinogenic compounds known as Advanced Glycation End-Products (AGEs) form. AGEs cause oxidative stress, generalised inflammation and premature ageing too.

Glyphosate is commonly found in processed foods – you may have heard of Glyphosate before. Glyphosate is the active ingredient in many gardening herbicides! It is linked to cancer and major damage to the gut microbiome. This is not an issue with fresh feeding, especially if you purchase your dog or cat’s raw ingredients from organic sources.

Fresh foods tend to be very low in carbohydrates; some vegetables contain carbohydrates, such as sweet potato, which may be fed in small quantities, but dry foods, and other processed foods are usually very high in carbohydrates; usually between 30% and 60% carbs! High carb foods cause blood sugar spikes, and can feed yeast, cancer, and lead to generalised inflammation. You can read more about carbohydrate consumption for dogs

here. Cats are obligate carnivores so should not consume any.

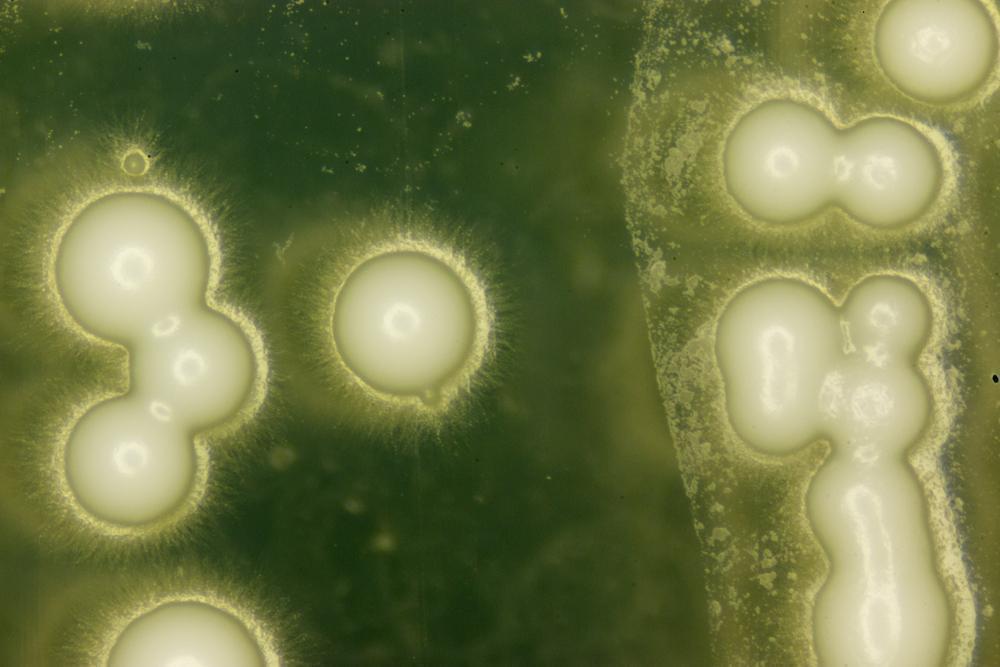

Finally, contamination of raw food is much lower than that of dry foods. Storage mites are a risk of dry food, but not of fresh foods as these are stored in the freezer. Mycotoxins and Aflatoxins are also commonly found in dry foods, due to their long dry-stored shelf life – again this is eliminated through freeze-stored fresh foods.

A frequently asked question regarding safety of raw food vs dry foods, is salmonella contamination. Between 2012 and 2021, 80% of recalls due to salmonella were in fact, of dry food! A group of scientists surveyed 16,412 pet owners from 81 countries; a grand total of 39 had reported human illnesses due to raw pet food – just 0.2% – 9 cases were in the UK. Practice proper food hygiene, just as you would when preparing your own meals, and raw feeding is incredibly safe!

Findings Here

Manufacturing Raw Food

Raw food manufacturing is extremely stringently controlled, and foods are DEFRA tested… more stringently so than raw meat sold for human consumption!

Commercially prepared raw food is, in most cases, produced on a cold chain production line. Sound fancy doesn’t it? But what is ‘cold chain processing’? The meat comes into the factories in temperature controlled lorries. The meat is kept below a certain temperature throughout the manufacturing process – it is always kept either frozen or extremely cold at all times, leaving little room for bacterial growth.

Once the products are minced, and packaged, they are stored in a deep freeze at below -18

oC, before being transported for sale in temperature controlled packaging/vehicles.

As you can see, this method is perfect for keeping nutrients intact and to their full potential. Premade raw foods are available for both cats and dogs!

Preparing Raw Food at Home

If you choose to make your own raw meals, commonly known as DIY, you may wish to freeze your meat first. Freezing is believed to eliminate the potential risk of parasitic burdens in meat, though little scientific scripture is available to prove, or disprove this theory – it may be best to err on the side of caution. As a basic guide, freezing lengths should be as follows:

- Game, pork and fish: 3 weeks OR deep freeze

- Other meat: 1 week OR deep freeze

Findings Here

Findings Here

The ratio tends to be 80% muscle meat, 10% bone, 5% liver and 5% other secreting offal such as kidney, pancreas, testicle, spleen, brain etc. Heart and tripe are classed as muscle meat, not offal.

To make this 80-10-10 mix into a complete meal, you will need to add plant matter, and omega sources. You can learn more about balancing an 80-10-10

here.

If you are considering a DIY raw diet, and you want to learn all there is to know about the ins and outs of raw feeding, you can purchase our fantastic

Ultimate Raw Feeding Guide for Dogs.

Manufacturing Cooked Food

Cooked foods are relatively new to the pet food market, with varieties available for both cats and dogs.

Ingredients arrive fresh at the factories in temperature controlled vehicles, before being chopped to size, usually by hand, and cooked in large batches, at low temperatures. Temperatures of all ingredients are regularly checked to avoid bacterial growth, and ensure the food is properly cooked. Due to the nature of manufacturing, and minimal processing, these meals are rich in moisture!

The cooked meals are then packaged, and in most cases, frozen in a deep freeze before being transported to retailers or directly to customers in temperatures controlled vehicles/cool box style packaging.

Preparing Cooked Food at Home

If you are planning to cook for your dog at home, you will need to follow a recipe balanced to FEDIAF. FEDIAF guidelines state the minimum amounts of each nutrient required to be a complete and balanced food. These recipes can be cooked in bulk, and frozen in portions for longevity. The first few days worth can be kept in the refrigerator.

When following your chosen recipe, it’s important to follow recipes exactly, to ensure nutritional guidelines are met.

Cooked foods can be beneficial for those who don’t tolerate raw, so they can still benefit from fresh, moist foods. There are also recipes available on our website for specific health conditions!

Shop our recipes for healthy adults

here.

Shop our recipes for specific health problems

here.

Manufacturing of Freeze Dried

Relatively new to the market, freeze dried foods are one of the least denatured, minimally processed dry textured options. These foods are made using fresh ingredients, which are blended and shaped into nuggets, and placed inside a freeze drying machine. Inside the machine, the food is frozen, then pressure is reduced, and heat is added (at low temperatures), which in turn causes water in the ingredients to turn to vapour, and evaporate. Once the moisture is removed from the food, the nuggets become light, and crumbly. These can be rehydrated slightly using water before serving, if your dog enjoys a softer, paste-like texture.

Manufacturing of Dehydrated

One of the more natural methods of feeding, dehydrated foods start off using raw ingredients, in balanced proportions. Unlike raw feeding, these ingredients don’t stay raw. Dehydration is essentially where the moisture is sucked out of the foods, creating a dry textured food, generally lower in carbs than other dry foods.

The lack of moisture isn’t the only downside to dehydrated foods – they are also subject to heat during manufacture. The difference between the heat these foods are subjected to, and the heat kibble is subjected to, is vast though. The temperatures reached during dehydration of meat based products do not exceed 70

oC, so less nutrient breakdown occurs than in extruded dry foods.

To combat the lack of moisture, some brands recommend mixing their product with water before serving, in order to rehydrate it.

Manufacturing of Air Dried

To make a complete, air dried food, a sort of dough has to be formed rolled our or formed, and dried. Unlike kibble and cold pressed, the raw ingredients are not processed and ground into a powder under extreme heat before dough formation. Instead, they are minced in their raw state, and mixed together. To ensure they stick into a mouldable dough, some form of carb has to be used – sweet potato is a common starchy ingredient used in air dried foods.

The drying process itself, requires hot air to be blown over the mixture for a fairly long period of time. This results in a dry textured food, with less processing and less heat exposure than kibble and cold pressed foods, resulting in a much lower risk of Advanced Glycaemic End Products.

Manufacturing of High Quality Wet Foods

Wet foods can hugely vary in quality. Some high quality examples will be 80-95% meat. The ingredients are mixed together, usually raw, and put into tins. The tins are then cooked in a water bath or similar, locking more nutrients inside the tin, and naturally preserving it. These foods are high in moisture, and tend to have a fairly ‘chunky’ texture.

Manufacturing of Low Quality Wet Foods

Lower quality wet foods tend to be much more processed, with a very mushy texture, or reformed into identical lumps, canned with sugary, salty ‘gravy’ or ‘jelly’. The ingredients will be blended and subject to heat, before being pushed through a shaped tube and cut into pieces. The pieces will be cooked and added into tins with the gravy or jelly mixture (which invariably contain preservatives), the tins will be sealed, and subject to further heat before being packaged for sale. These foods tend to give off a strong odour when opened.

Manufacturing of Kibble

The vast majority of kibbles are ‘extruded’. Extrusion is the process of forcing the dough through plates to form shapes.

Many kibbles state they are made from ‘raw meat’, however in order to make them into bits of kibble, they have to form a dough. All ingredients need to be ground down into a powder-like form, and mixed with a wet ingredient to create that dough.

When the ingredients arrive at the factory, they are usually in their while state – this includes vegetables, grains, and meat; meat can be anything from actual muscle meat, to offal, to feathers, beaks, tendons etc depending on which cuts and quality of meat the individual manufacturer uses in their recipes.

These ingredients are cooked and ground down to a fine powder. Most are heavily processed to create ingredients you may see such as ‘pea protein’, ‘meat meal’, ‘maize gluten meal’ etc. This stage requires

high temperatures.

These powders are then mixed with synthetic supplements to replace some of what is lost in the processing of the whole ingredients.

High temperatures are introduced again during the mixing process when water or oil is added, to enable the formation of a dough.

The dough is then subject to extremely

high temperatures and pressure where it is cooked to create the brown coloured (or multi-coloured, if colourings are added with the supplements), dense textured dough, ready to be extruded.

The product is then pushed through the extrusion machine to form small shapes, before being subject to a fourth and final

high temperature as they are dried in an oven.

Before packaging, the kibble is sprayed with a coating of flavour enhancers and preservatives.

Manufacturing of Cold Pressed

Similarly to kibble, the whole ingredients are delivered to the factory, and are subject to heat and processing to form a powder.

Once in powder form, they are mixed with supplements, and water. The water mixed into the dough of cold pressed food, is cold, unlike that mixed into the dough of kibble.

The dough is cooked quickly, and at low temperatures, before being pressed into a die, dried, and packaged.

We hope this blog has been useful to you, and helps you understand the manufacturing process of pet foods on the market, highlighting the disadvantages of processed foods. If you would like help switching your pet to a fresh cooked diet, please do not hesitate to book in with on of our team. Our Optimise Packages for cats and for dogs would be ideal.

Team MPN x